Machines help people work better and faster in many places. In factories, machines do many jobs now. These machines are part of industrial automation. They follow instructions and do the same job again and again.

Automation makes work easier for humans. It helps save time and money. Workers can focus on harder jobs. The machines take care of simple and boring tasks. This makes everything run better.

Many industries use automation today. These include car factories, food plants, and packaging lines. Companies use automation to stay ahead. It helps them make more things in less time.

Table of Contents

What Is Industrial Automation?

Industrial automation means using machines and computers to do work. It replaces some tasks that people used to do by hand. These machines do jobs like moving parts, packing items, or checking quality.

Automation makes things faster and safer. Machines do not get tired or make mistakes easily. They follow the same steps every time. This helps companies keep the work smooth and on time.

Why Do Industries Use Automation?

Automation helps cut costs. Companies spend less money on labor. Machines work for long hours without stopping.

It also improves product quality. Machines do the same job in the same way every time. This means fewer mistakes. Customers get better products.

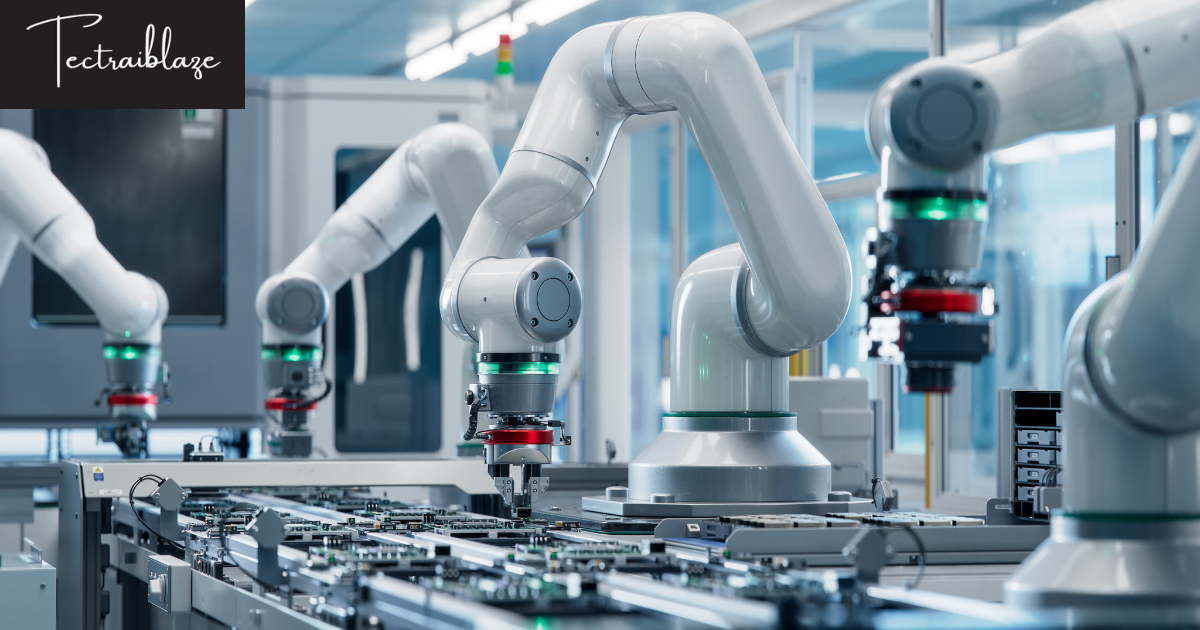

Assembly Line Automation

Assembly lines use machines to build products. Robots put parts together step by step. This is common in car and phone factories.

These machines move quickly and do the job right. They work all day without breaks. This helps factories make many products fast.

Material Handling

Material handling means moving items from one place to another. Conveyor belts and robotic arms do this job. They carry boxes or parts around the factory.

These systems help save time. Workers do not have to carry heavy items. This also keeps the work area safe and clean.

Quality Control Systems

Machines now check if products are made correctly. These systems use cameras and sensors. They find errors in size, shape, or color.

This helps stop bad products from reaching customers. It also saves money. Companies do not have to fix or throw away bad products later.

Packaging and Labeling

Robots now pack products in boxes. They also place labels on items. This happens fast and without mistakes.

Proper packaging protects the product. Labels help people know what is inside. Automation makes sure every box looks the same.

Welding and Painting Robots

Many factories use robots for welding and painting. These robots can work in hot or dangerous places. They wear no safety gear and never get tired.

Welding and painting need care. Robots do these tasks better than people. They follow the same path every time and make smooth finishes.

Inventory Management

Factories track parts and products using automation. Systems scan barcodes and record numbers. This helps know what is in stock.

Good inventory saves money. It stops companies from running out of parts. It also helps them order new parts on time.

Process Control Systems

Process control systems check and control machines. They manage things like heat, pressure, and speed. These systems run machines the right way.

This is used in food, oil, and chemical plants. The system makes sure everything stays safe. It also helps keep the product the same every time.

CNC Machines

CNC stands for Computer Numerical Control. These machines cut and shape metal or wood. Workers give them a program, and the machine does the job.

These machines are very accurate. They make parts that fit perfectly. This helps in industries like car making and furniture.

Industrial Robots

Industrial robots can do many jobs. They move, lift, weld, and assemble. You see them mostly in big factories.

They help people with hard or risky jobs. They work fast and never stop. This keeps production going smoothly all day.

Safety and Monitoring Systems

Factories need to be safe. Automation helps with that too. Systems check for fires, gas leaks, and equipment problems.

These systems send alerts fast. Workers can stop machines and stay safe. This protects both people and equipment.

Data Collection and Reporting

Modern machines collect data all day. They record how much they make and how long it takes. They also check for problems.

This data helps managers make good decisions. They can see what works well and what needs to change. It helps improve everything over time.

Energy Management

Factories use a lot of power. Automation helps save energy. It turns machines off when they are not needed.

This saves money and helps the environment. Energy systems also find where power is wasted. Then companies can fix those areas.

Maintenance and Repair Alerts

Machines now tell you when they need fixing. Sensors watch for strange sounds or heat. They give alerts before the machine breaks.

This helps stop sudden stops in work. It also saves money. Fixing things early is better than waiting too long.

FAQ’s

What is industrial automation?

It means using machines to do work in factories.

Why do companies use automation?

It saves time and money and makes fewer mistakes.

Can machines do all the work?

No, people still guide and fix the machines.

Is automation safe?

Yes, it makes work safer when used correctly.

What industries use automation?

Car, food, packaging, and many others use it.

Conclusion

Industrial automation helps many companies. It makes work faster, safer, and better. Machines take care of boring or hard tasks.

Workers still play an important role. They run the systems and solve problems. With automation, they do smarter work.

In the future, more industries will use machines. Automation keeps growing and improving. It is a big part of our working world now.